Wet Ball Mill

A variety of models are available | Get the free price list!

- Wet ball mill is a rolling bearing, high efficiency and energy saving ball mill. It is commonly used for grinding ores with coarse particle size.

- effective volume:1.14-41.5m³

- Cylinder diameter:1200-3600mm

- Capacity:0.17-180t/h

What is Wet Ball Mill?

Wet ball mill, also called wet energy saving lattice type ball mill, adopts grooved ring liner, which increases the contact surface of ball and ore, strengthens the grinding effect, and has lifting capacity for ore and reduces energy consumption.

According to the loading of grinding media can be divided into ball mill, rod mill and self-grinding mill without media.

If you are a beginner and do not know about Wet Ball Mill, tell us your raw material characteristics, finished product requirements, site conditions, production budget, hourly production, and other requirements, we have professional engineers to equip you with a suitable model at a reasonable price. Next, let’s see the types of Wet Ball Mill we can supply.

Table of Contents

- What is Wet Ball Mill?

- What Is Wet Ball Mill Used For?

- Wet Ball Mill ordered by Customer

- Technical Parameters of Wet Ball Mill

- Working Principle of Wet Ball Mill

- Advantageous features of Wet Ball Mill

- What can ChunLei do for you-about service?

- Wet Ball Mill price

- You may also want to know about ChunLei-FAQ

What Is Wet Ball Mill Used For?

Wet ball mill is an important equipment in the grinding process, mainly placed after the crushing equipment, is the key equipment for coarse gravel materials to be crushed again. It is characterized by high crushing ratio, good reliability, strong adaptability and large processing capacity.

For example: At the early stage of the establishment of a certain mineral processing plant, the grinding system used an ordinary ball mill, which caused the phenomena of spitting chunks and abnormal fracture of the liner due to the liner, resulting in the ball mill could not work normally. In order to solve this problem, Chunlei’s wet ball mill was chosen. The ball mill adopts wave-shaped liner, toughness enhancement at the same time the ball-mineral contact area becomes larger, the grinding effect is strengthened, the material particle size is more controllable. Eventually the whole production process is carried out efficiently.

Wet Ball Mill ordered by Customer

Chunlei Machinery has been engaged in mining machinery manufacturing for more than 30 years, with a wealth of experience in building websites and customer cases, served customers all over the world!

Technical Parameters of Wet Ball Mill

| Model | Cylinder diameter (mm) | Cylinder length (mm) | Motor Model | Motor power (kW) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective volume (m3) | Maximum ball loading(t) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MQ 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQ 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26 ~6.15 | 2.4 | 4.6 | 12692 |

| MQ 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQ 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4~4.5 | 2.2 | 5 | 17125 |

| MQ 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQ 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQ 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQ 1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQ 1836 | 1800 | 3600 | JR136-8 | 180 | 8866 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQ 1845 | 1800 | 4520 | JR137-8 | 210 | 9808 | 3683 | 2785 | 5~35 | 10.2 | 19 | 38909 |

| MQ 1856 | 1800 | 5620 | JR137-8 | 210 | 10909 | 3683 | 2785 | 6~40 | 12.2 | 22 | 41681 |

| MQ 1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQ 2122 | 2100 | 2200 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQ 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQ 2136 | 2100 | 3600 | JR137-8 | 210 | 9154.5 | 4320 | 3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQ 2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5 ~45 | 12.8 | 22.5 | 47262.4 |

| MQ 2145 | 2100 | 4500 | JR137-6 | 280 | 10350 | 4253 | 3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQ 2230 | 2200 | 3000 | JR137-8 | 210 | 8220 | 3864 | 3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQ 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 59544.5 |

| MQ 2436 | 2400 | 3600 | JR138-8 | 320 | 9604.5 | 4836.4 | 3490 | 8 ~100 | 13.8 | 25.5 | 63932.5 |

| MQ 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3490 | 8 ~110 | 16 | 30 | 67370 |

| MQ 2721 | 2700 | 2100 | JR138-8 | 245 | 8300 | 4786.4 | 3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQ 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQ 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610 | 5000 | 3495 | 8 ~115 | 15.3 | 32 | 83909.2 |

| MQ 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQ 2736 | 2700 | 3600 | JR158-8 | 380 | 10409 | 5150 | 3620 | 12~145 | 17.7 | 37 | 95300 |

| MQ 2740 | 2700 | 4000 | JR158-8 | 380 | 10609 | 5150 | 3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQ 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534 | 5200 | 3670 | 13~160 | 22 | 40 | 100016 |

| MQ 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779 | 5571 | 4175 | 13~170 | 23 | 45 | 101645 |

| MQ 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299 | 5540.6 | 5140 | 15~200 | 30 | 60 | 119546 |

| MQ 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964 | 5350 | 3670 | 13~160 | 19.7 | 41 | 106350 |

| MQ 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5150 | 14~180 | 22.5 | 45 | 115430 |

| MQ 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 147588 |

| MQ 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280 | 7700 | 5496 | 115~170 | 41.5 | 76 | 195727 |

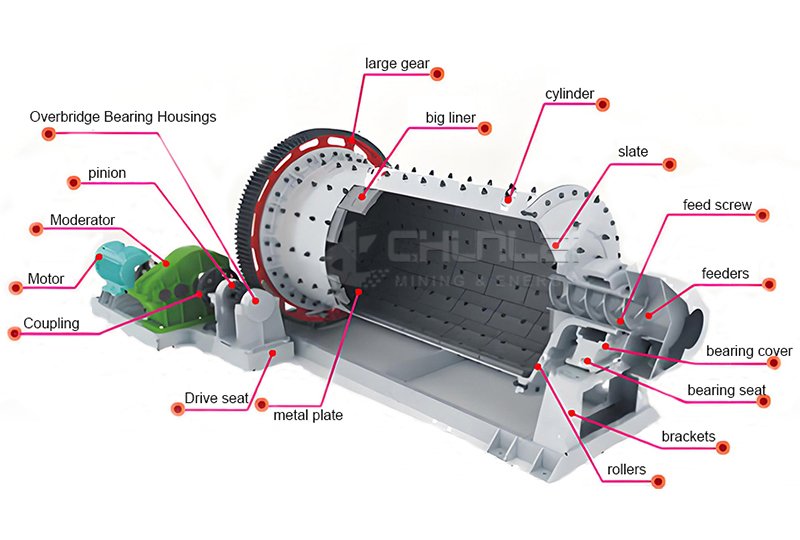

Working Principle of Wet Ball Mill

Wet ball mill through the transmission device to make it rotate slowly, the material from the cylinder feeding end to feed, in the cylinder due to the steel ball and the ore itself to throw down the impact and self-grinding, the material can be crushed. Due to the continuous feeding of materials, the pressure prompts the materials in the cylinder to move from the feeding end to the discharging end. The material that reaches the finished size is discharged from the discharge end of the cylinder.

When wet grinding, the material is carried out by water flow; when dry grinding, the material is carried out by air flow.

Advantageous features of Wet Ball Mill

- The transmission of wet ball mill adopts large double-row spherical roller bearings instead of sliding bearings, which greatly reduces the friction, easy to start and saves 20-30% energy.

- Adopting wave-shaped liner, increasing the ball-ore contact surface, strengthening the grinding effect, and the lifting capacity of the ore, reducing energy consumption.

- Large discharge opening, large production capacity.

- Small mills with a diameter of less than 2.1 meters (not including 2.1 meters), adopting an integral frame, which is convenient for civil construction and equipment installation.

- Oil mist lubrication device to ensure reliable lubrication of large and small gears.

What can ChunLei do for you-about service?

Pre-sales service

1. Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

In-sales service

1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

After-sales service

1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

Wet Ball Mill price

As for the price, we can’t show you the exact price because we deal with customers from all over the world and there are many factors affecting the price. If you want to know the price of Wet Ball Mill, you can leave a message to us on this page, we have professional sales staff and engineers to explain to you.

As one of the old brand mining machinery manufacturers in Henan, Chunlei Machinery strictly controls every Wet Ball Mill for sale with more reliable quality. Chunlei has its own R&D team and production site, and sells directly, enjoying factory super low price. What are you waiting for? Contact us immediately!

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Related Products —

Dry Rod Mill

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill, wet rod mill. Different from the ball mill is built-in rod mill is a steel rod type grinding body, the use of cy…

Wet Gold Separation Ball Mill

A variety of models are available | Get the free price list! Firstly, let’s introduce the main ore processed by gold separating ball mill – gold ore.Gold ore is the ore that contains gold elements or gold compounds. …

Raymond Mill

A variety of models are available | Get the free price list! Raymond mill adopts a number of patented technologies such as bevel gear integral drive, internal thin oil lubrication system, arc air ducts, etc., with…

Autogenous Mill

A variety of models are available | Get the free price list! The autogenous mill, also called ultrafine laminar autogenous mill/semi-autogenous mill, is a new type of autogenous mill, which is a kind of grinding e…

Wet Rod Mill

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill, wet rod mill. Different from the ball mill is built-in rod mill is a steel rod type grinding body, the use of cy…

loading…

已经是到最后一篇内容了!

Chunlei Mining Machinery

Chunlei Mining Machinery