Screw Sand Washing Machine

A variety of models are available | Get the free price list!

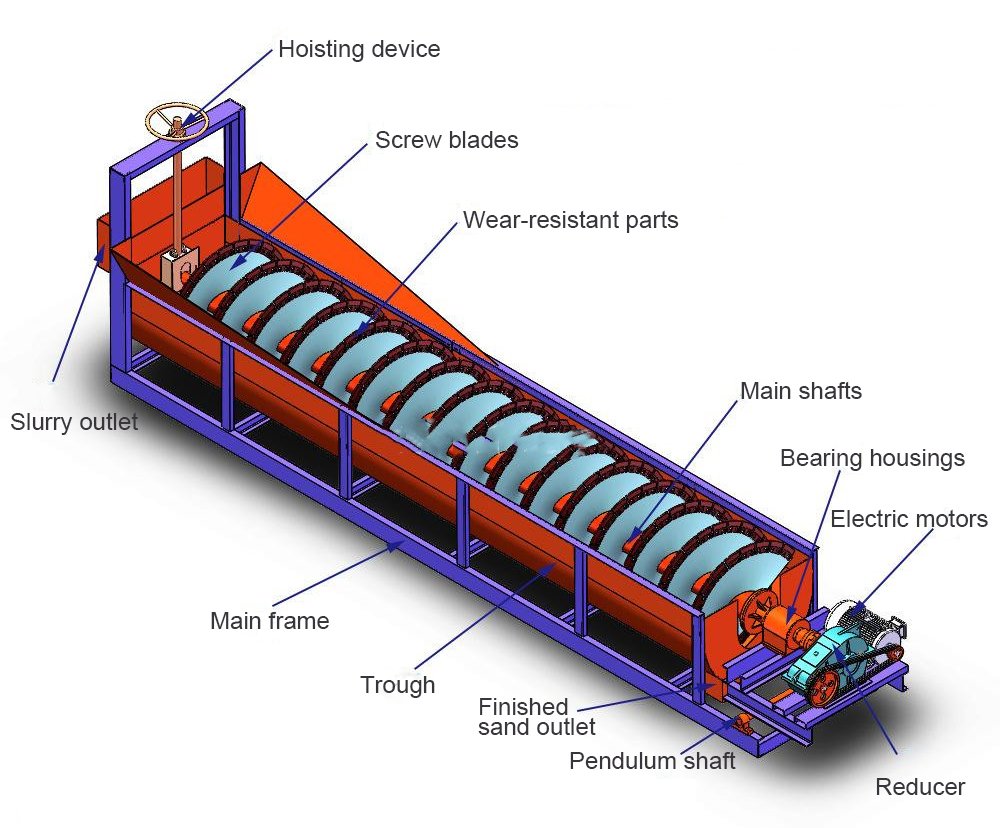

- Screw sand washing machine, also known as gravel washing machine or Spiral sand washer, can be divided into single screw sand washing machine and double screw sand washing machine due to the different number of screws inside the screw sand washing machine, there is only one screw inside the single screw sand washing equipment, and there are two screws inside the double screw sand washing equipment.

- Feed size:≤10mm

- Capacity:20-450m³/h

- Applicable materials: Sand and gravel washing machine is widely used in highway, hydropower, construction and other industries for washing, grading, removing impurities, as well as fine-grained and coarse-grained material washing and other operations, especially suitable for construction and road building sand and gravel.

What is Screw Sand Washing Machine?

Spiral sand washer is a generation of sand washing machine designed for sand and gravel washing and grading and dewatering, its special working principle, novel sealing structure, fully enclosed oil bath transmission device, adjustable overflow weir plate, to ensure that the series of products with high efficiency, durability, cleaning, dewatering effect is good, and the fine-grained products to maintain stability and other characteristics, welcomed by the majority of customers, has been successfully and widely used in the construction site, gravel It has been successfully and widely used in construction sites, sand and gravel factories, hydroelectric power stations, concrete dam sites, as well as foundry industry, glass manufacturing industry, oil well development industry and other sand-using units.

If you are a beginner and do not know about Screw Sand Washing Machine, tell us your raw material characteristics, finished product requirements, site conditions, production budget, hourly production, and other requirements, we have professional engineers to equip you with a suitable model at a reasonable price. Next, let’s see the types of Screw Sand Washing Machine we can supply.

Table of Contents

- What is Screw Sand Washing Machine?

- What Is Screw Sand Washing Machine Used For?

- Screw Sand Washing Machine ordered by Customer

- Technical Parameters of Screw Sand Washing Machine

- Working Principle of Screw Sand Washing Machine

- Advantageous features of Screw Sand Washing Machine

- What can ChunLei do for you-about service?

- Screw Sand Washing Machine price

- You may also want to know about ChunLei-FAQ

What Is Screw Sand Washing Machine Used For?

Spiral sand washer is mainly used in sand production line, it is the “scavenger” in the sand production line, which is mainly used to remove soil, dust and other impurities in sand and gravel. Spiral sand washer has strong crushing and dispersing ability to the fine mud clusters, and the sand and gravel are cleaner after cleaning.

Spiral sand washer is a kind of sand washing machine, mainly through the spiral device in the equipment to mix the sand and gravel material, so as to make the soil in the sand and gravel material mixed with water, and discharged from the flow port on the equipment, while the sand and gravel material is gradually screened under the action of the spiral device, and discharged from the discharge port on the top, so as to realize the cleaning and screening effect of the sand and gravel material.

Spiral sand washer is suitable for metallurgy, building materials, hydropower and other industries, such as washing, grading, removing impurities and other operations, sand and gravel aggregates in the fine and coarse grain size material cleaning.

Screw Sand Washing Machine ordered by Customer

Chunlei Machinery has been engaged in mining machinery manufacturing for more than 30 years, with a wealth of experience in building websites and customer cases, served customers all over the world!

Technical Parameters of Screw Sand Washing Machine

| Model | Spiral Diameter(mm) | Length of flume(mm) | Screw speed(r/min) | Capacity(t/d) | Motor power(kw) | Overall Dimension(mm≤) | ||||

| According to sand return | By overflow | Transmission | For lifting | Length | Width | Height | ||||

| LX-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | —- | 3850 | 490 | 1140 |

| LX-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | —- | 5430 | 680 | 1480 |

| LX-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | —- | 6720 | 980 | 1820 |

| LX-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | —- | 7590 | 1240 | 2380 |

| LX-10 | 8400 | 675-1080 | 85 | 7.5 | —- | 9600 | 1240 | 2680 | ||

| LX-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 |

| LX-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | ||

| 2LX-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | ||

| 2LX-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | ||

| LX-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 |

| LX-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | ||

| 2LX-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | ||

| 2LX-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | ||

| LX-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 |

| LX-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | ||

| 2LX-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | ||

| 2LX-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | ||

| LX-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 |

| LX-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | ||

| 2LX-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | ||

| 2LX-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | ||

| 2LX-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 |

| 2LX-30 | 14300 | 23300 | 1410 | —- | —- | 17091 | —- | 8680 | ||

Working Principle of Screw Sand Washing Machine

Spiral sand washer is generally tilted when it is installed, when it works, the spiral begins to rotate under the action of the motor, the material is fed evenly from the feed box, and a certain amount of water is continuously injected into the main tank, the transmission department drives the spiral shaft to rotate at a certain speed, forcing the material to turn over and roll in the tank and move towards the discharge port, the fine-grained material and impurities are discharged along with the overflow water through the overflow weir, and coarse-grained material is discharged by the discharge port, thus realizing the material washing, grading, removing impurities and dewatering. Thus realizing the washing, grading, removing impurities and dewatering of materials, and completing the cleaning of sand and gravel.

Advantageous features of Screw Sand Washing Machine

- High cleanliness: the sand and gravel cleaned by the spiral sand washer, especially the fine sand is cleaner than the wheel bucket sand washer, but its efficiency is relatively low, the materials cleaned by the spiral sand washer can meet the requirements of high-grade materials.

- Low failure rate, long life: the rotating part of the spiral sand washer is isolated from water and sand, so its wear and failure rate is greatly reduced, and the service life becomes longer, which saves the secondary input cost of the spiral sand washer in the process of using.

- Simple structure: the sand washer has a simple structure, stable operation, and it is convenient for overhaul and maintenance.

- Sewage can be recycled: the sewage after washing the sand through the sedimentation tank and for re-use, saving resources and reducing investment costs.

What can ChunLei do for you-about service?

Pre-sales service

1. Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

In-sales service

1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

After-sales service

1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

Screw Sand Washing Machine price

As for the price, we can’t show you the exact price because we deal with customers from all over the world and there are many factors affecting the price. If you want to know the price of Screw Sand Washing Machine, you can leave a message to us on this page, we have professional sales staff and engineers to explain to you.

As one of the old brand mining machinery manufacturers in Henan, Chunlei Machinery strictly controls every Screw Sand Washing Machine for sale with more reliable quality. Chunlei has its own R&D team and production site, and sells directly, enjoying factory super low price. What are you waiting for? Contact us immediately!

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Related Products —

Wheel Sand Washing Machine

A variety of models are available | Get the free price list! What is wheeled sand washer? Wheel sand washer is a kind of wheel bucket washing equipment, is artificial sand, river sand, sea sand, or crushed glass a…

Fine Sand Recycling Machine

A variety of models are available | Get the free price list! Fine sand recycling machine is for slurry material dewatering, de-mediation, desludging development of equipment, through the slurry pump will be the co…

Sand Making Machine

A variety of models are available | Get the free price list! Sand making machine is also known as impact sand making machine, impact crusher, vertical impact crusher, or impact breaker for short. It consists of seven…

loading…

已经是到最后一篇内容了!

Chunlei Mining Machinery

Chunlei Mining Machinery