Gold Mine CIP Carbon-in-pulp Production Line

Process Introduction

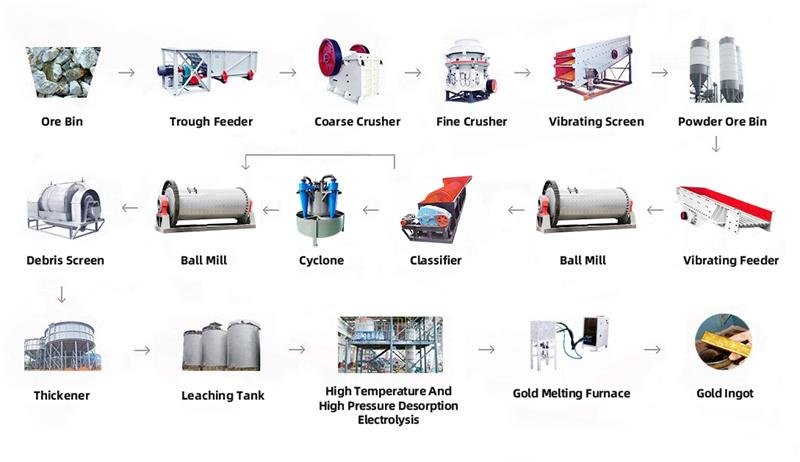

Gold CIP (Carbon in Pulp) is a non-filtered cyanide carbon slurry process that recovers gold from cyanide slurry through activated carbon adsorption. Its main steps include preparation of leaching slurry, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, electrolysis to obtain gold mud, and recycling of gold-removed carbon.

What Is Gold Mine CIP Carbon-in-pulp?

Gold CIP (Carbon in Pulp) line is a process line used to extract gold from gold bearing ores. It is mainly used in gold mining and metallurgical industry, especially for the recovery of low-grade gold ores, complex and difficult to select gold ores as well as associated gold in polymetallic ores is of great significance.

Gold Mine CIP Carbon-in-pulp Production Line Process

Application Field: CIP carbon slurry production line can effectively extract gold from low-grade gold-bearing ores, improve the utilization rate of resources, reduce production costs, and provide an economically feasible technical means for the development and utilization of low-grade gold ores.

The CIP carbon slurry process can adsorb gold directly from the ore slurry without solid-liquid separation, which is especially suitable for the treatment of muddy oxidized ores.

Main Equipment: Jaw Crushers, Ball Mill, Hydrocyclones, Vibrating Screens etc.

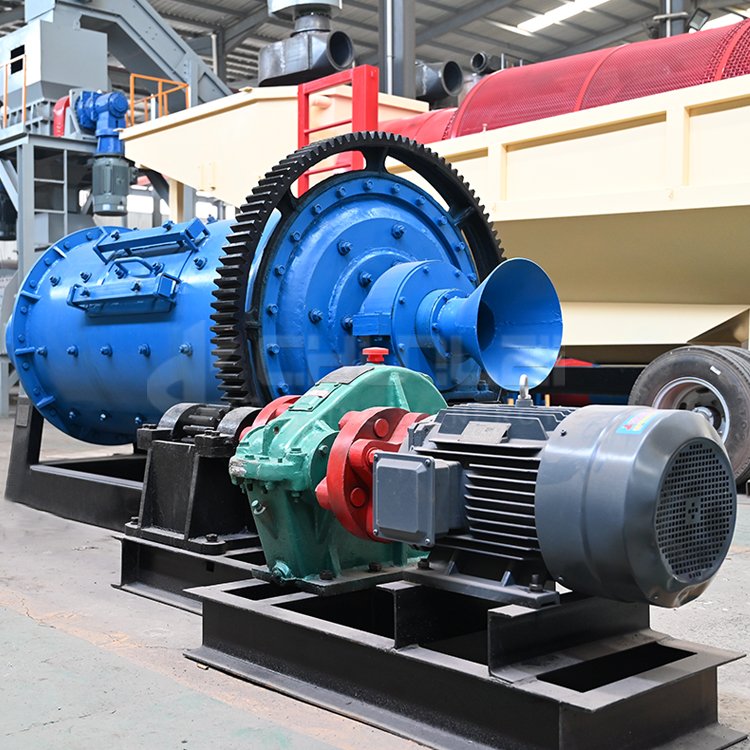

Main Equipment

Advantageous features of Gold Mine CIP Carbon-in-pulp

- High adsorption rate and high recovery rate: Activated carbon has high adsorption capacity and can effectively recover gold from slurry.

- No filtration step: The CIP process eliminates the expensive solid-liquid separation process, simplifies the process and reduces production costs.

- Optimize production links: By optimizing each production link, production efficiency is improved.

- Suitable for complex ores: The CIP process is particularly suitable for ores that have undergone complex smelting reactions, and can significantly improve production efficiency and reduce chemical and electricity consumption.

In short, the CIP carbon slurry method is an efficient and economical gold extraction process and is widely used in the gold mining industry.

How To Choose The Right Gold Mine CIP Carbon-in-pulp For Sale

Choosing the right Gold Mine CIP Carbon-in-pulp requires careful consideration of several key factors. This is a guide to help you understand how Gold Mine CIP Carbon-in-pulp works.

Understanding your project needs

Begin by assessing the specific needs of your project. Consider the size of the beneficiation, the climate of the location and the type of material required. Different projects require different production levels, mixing accuracy and environmental standards. Be sure to thoroughly evaluate these factors before making a decision.

Considering equipment output

Plant capacity is critical. Match the capacity of the equipment to your project schedule. For large projects, choose a high-output model to meet demand. For smaller or segmented projects, a mid-sized or small plant may be more appropriate.

Focus on environmental factors

As environmental regulations continue to tighten, it is vital that plants are eco-friendly. Choose equipment with advanced environmental features, such as low-noise design. This not only ensures compliance, but also enhances your company’s image.

Prioritize stability and ease of operation

Stability and ease of operation have a direct impact on efficiency and cost. Choose a plant with automated control systems to minimize human error and increase productivity. Also, consider maintenance costs and the lifespan of key components to ensure consistent performance over time.

Evaluating after-sales service and technical support

Reliable after-sales service and timely technical support are critical. Good support can solve problems quickly, minimize downtime and keep your project on track.

Plan your budget wisely

While the initial investment in mineral processing can be high, choosing durable, stable equipment will provide better returns in the long run. So it’s important to consider not only the purchase price, but also the operating costs, maintenance costs and potential environmental impact.

By taking these factors into consideration, you can find the beneficiation line that best suits your project’s needs, ensuring smooth operation and maximizing your investment.

What Projects Gold Mine CIP Carbon-in-pulp Can Be Used in?

What are the different uses of Gold Mine CIP Carbon-in-pulp? Here are a few items that are often used gold ore flotation production line for sale, highlighting their unique features. When choosing a Gold Mine CIP Carbon-in-pulp, consider factors such as the temperature of the material and climate, not just the application area.

Separation of useful minerals from chalcopyrite minerals for mineral processing and purification

Through various beneficiation methods, such as re-election, flotation, magnetic separation, etc., the useful minerals are separated and the grade of the minerals is improved.

For example, in iron ore beneficiation, the iron-bearing minerals are separated from the quartz and other veinstones to obtain a high-grade iron ore concentrate.

For non-ferrous metal ores, impurities can be effectively removed to provide high-quality raw materials for the subsequent smelting process.

Recovery of valuable elements

Many ores contain a variety of valuable elements, and the beneficiation production line can recover these elements separately.

Tailings Re-election

The tailings produced in the beneficiation process usually contain a certain amount of useful minerals, and the beneficiation production line can re-elect the tailings to recover the residual value.For example, in the gold mine tailings re-election, the use of flotation technology can recover some of the residual gold minerals and improve the total recovery rate of gold.

The beneficiation production line can be adapted to the needs of different industries, such as metallurgical industry, chemical industry, building materials industry and so on.

Metallurgical industry

Provide high-grade raw materials for iron and steel, non-ferrous metal smelting.

Chemical industry

To provide specific quality mineral raw materials for chemical production

Building Material industry

Provide mineral raw materials for building materials.

What can ChunLei do for you-about service?

Pre-sales service

1. Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

In-sales service

1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

After-sales service

1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

What is the Price for Gold Mine CIP Carbon-in-pulp?

When considering Gold Mine CIP Carbon-in-pulp prices, it is important to match your budget with the right model. Whether you need a cost-effective solution or high capacity production, both series of ChunLei Machinery offer excellent options to meet your specific needs.

As one of the old brand mining machinery manufacturers in Henan, Chunlei Machinery strictly controls every product for sale with more reliable quality. Chunlei has its own R&D team and production site, and sells directly, enjoying factory super low price. What are you waiting for? Contact us immediately!

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, established in 2008.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Contact Us

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!

Chunlei Mining Machinery

Chunlei Mining Machinery